I.Product introduction of Ginde PE-RT pipe

Ginde raised temperature resistant polyethylene (PE-RT) pipe ---- the raise temperature resistant polyethylene total plastic pipe system with excellent performance, as the advantages of excellent hydraulic pressure resistant performance and special construction, it becomes the best in the low temperature hot water floor radiation heating pipes.

Properties of Ginde PE-RT pipe

1. Light weight: easily transported and installed.

2.The excellent flexibility makes convenient and convenient when paving, the pipe of XZ89830.00 can decrease the consumption of the pipe fittings by coiling and bending and so on methods, decreasing the construction cost;

3.When the pipe is bent, the stress of the bent part will loose quickly, it is not suitable to appear “back”, convenient for construction operation, so it can prevent that as the stress concentrates in using process the pipe will break down in bending place;

4.The friction loss in pipe is low, the transporting fluid ability of this pipe is 30% more than the metal pipe with the same diameter,

5.Low brittle rupture temperature, the XZ89930.00 pipe material has excellent low temperature resistant performance, so it can construct under the consideration of low temperature in winter, and there is no need for preheating, which can solve inconvenience that it is too cold to construct in the north area of our country, Good chemical corrosion resistance, no rust, long lifetime;

6.Hot-melting connection, forming full closed seepage prevention system;

7.Good environment suitability

8.Under normal condition, the pipe can be used safely for 50 years;

9.The XZ 89830.00 has passed the health permission of FDA and TUV, the pipe doesn’t add any poisonous auxiliaries, it doesn’t foul in inner wall, doesn’t breed bacteria, so it can be applied in domains of potable water transportation;

10.Good resistance to impact performance;

11.Good heat dispersion, a lot of energy can be saved in the heating application.

2. The raw materials for production

The raw material of the Ginde PE-RT tubing is the polyethylene XZ89830.00 which is produced by the USA Dom chemical company. This raw material has particular molecular structure. It talks the linear ethylene as main chain, with the controllable branch, so it has excellent hydraulic pressure resistant performance. The XZ89830.00 can be connected by radiation without any cross-linking agent. The tubing performance after cross connection will exceed the requirement of the DIN16894 (PE/MD-X). The pipe from XZ89830.00 is smooth in inner and outer wall, which can decrease stopping as the piling up of the leftover in water. At the same time, the pressure loss in the transportation process is also decreased. Secondly, the PE-RT series product has no need for the cross connection technique, avoiding the trouble that the cross polyethylene controls the cross degree and uniformity.

3. Product specification

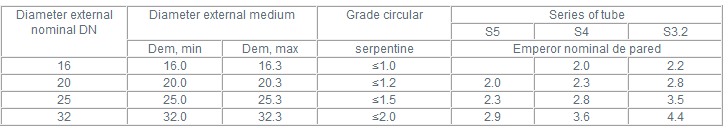

The Ginde PE-RT floor heating pipe has three series according to the sizes, which are S5, S4 and S3.2. Each series has four products: ø16, ø20, ø25, ø32.

The tubing series and standard size

Diameter external nominal DN Diameter external medium

Grade de circular Series of tube

S5 S4 S3.2

Dem, min Dem, max serpentine Espesor nominal de pared

16 16.0 16.3 ≤1.0 2.0 2.2

20 20.0 20.3 ≤1.2 2.0 2.3 2.8

25 25.0 25.3 ≤1.5 2.3 2.8 3.5

32 32.0 32.3 ≤2.0 2.9 3.6 4.4

Patent

Name Patent kind Time Application no. Remark

One pipe fitting for hot melting connection PE-RT pipe fitting 2001.11.16 01338654.9 Certification

1.Brief introduction:

In the plastic pipe application of hot water cycling system, metal materials of metal instruments shall be easier to occur abnormal, speedy corrosion, and equipments accelerate its damages, with this reasons of the oxygen permeability on the plastic pipe, as the temperature gets higher, this feature are more apparently shown on it. When pipe stars to be convey higher temperature fluids, it becomes easier for oxygen molecules penetrating through plastic layers, and then dissolves the fluids; it is this kind of oxygen that results in accelerating aging for the equipments. By means of the composite layers between PE-RT plastic pipe and a layer of high molecule oxygen resistance materials(EVOH), it ensures to produce the oxygen resistance pipe, it has been specifically shown in the technical materials that oxygen permeability quantities attains to be more than 0.1mg/L a day when the temperature of hot-water rises to 40℃. It occurs heavy corrosion for metal heater, metal valve, brass fitting, heating appliances, and water pumps in the heating system, therefore, oxygen resistance type plastic pipe are widely used in Europe, in the heating system, it all has been required for the application of oxygen resistance, heating plastic pipes in the areas of U.S.A. Europe and Australia. Aiming at current international market, demands larger quantities of oxygen resistance pipes. We strive for the development of five layers composite under floor plastic pipe, it features the following characteristics.

1.Pipe that shall be co-extruded from mould. In contrast to other techniques, it features excellent fluidity for hot-melt adhesive and higher adhesion strength with EVOH.

2.On-line inspection for the increase of pressure: after pressure rises to 0.6-0.8MPa, EVOH tightly connects with plastic, improve adhesion strength.

3.Synchronization computer controller

In the whole production line adopts computer controlling, when production velocity changes, it only requires to input digits of production velocity, and other parameters by computer automatic controlled.

4.Optic inspection apparatus:

Pipe wall quality and outer diameter for pipe controller.

It features:

Higher temperature and pressure resistance, higher elasticity, Lower creep resistance properties, without corrosion,

Widely usage application:

Cold and hot water cycling system, air conditional system, heating system.

2.Adaptability scope:

1)it applies in the heating appliances in the domestic living room, bedroom, public bathroom, swimming pool, kindergarten, bedroom, public bathroom, swimming pool, kindergarten, bead house, and also used as floor pipe for heating appliance, for example: airport expressway, and melting snow pipe for city building.

2)Higher temperature radiator, concentration heating system in the residential houses.

3)Cold and hot water application for buildings, pipeline potable water system.

4)Tubing in the domestic water heater system and all kinds of joint pipe.

5)Fluid conveyance pipe for beverage, wines, and milk in food industry.

6)Fluid conveyance pipe for chemical and oil industries.

7)Refrigerating pipeline system and water treatment pipeline system.

8)Other pipes in the industrial use.

3.The characteristics of the low temperature hot water floor radiation heating

1.comfortable and heath: heat transfer by radiation indoor, making the indoor floor temperature uniform, the indoor temperature decreases from down to up, which meets with the Chinese medicine health protection theory of “to heat person, heat foot firstly”, “heating foot and cold hand”, and as the flow speed of the floor radiation heating air is low, which can decrease effectively dust rising.

2.high efficiency energy saving: under the precondition of comfortable, the temperature of the low temperature hot water floor radiation heating method is 2-3 degree than traditional heating method, the heat efficiency is high, 30% of energy can be saved, the heating source range is wide, the remaining heating can be used.

3.Saving space: the indoor area is not used, effective usable area can be increased by 2-5 square meters (compared with the heating by the radiator), convenient for finish and furnishings arrangement.

4.safe used, the lifetime can reach up to fifty years, because the pipe buried under floor is paved with whole body, no joint, preventing thoroughly leaking.

5.convenient for management: as the initial end and terminal of the floor heating pipe mostly concentrates in the water separator and collector, convenient for heating power calculation, the individual charging can be realized. When the hot network is heating, meter can be read with computer.

6.Low running fee: as the low temperature floor radiation heating takes the low temperature hot water, saving fuel, easy for operation and management, safe and reliable, economic and practical.

7.Sound insulation: as special floor structure of the floor heating, when the upper and under course do not heat, the heating effect of the middle course is not affected. The heating medium is slow in the pipe, and the temperature protection course takes action of sound insulation, decreasing largely the noise interference between the upper and under course.

8.Good heating stability: the thermal storage capacity of the floor and concrete earth course is large, good heating stability, under the condition of intermittently heating: the changing of the indoor temperature is low.