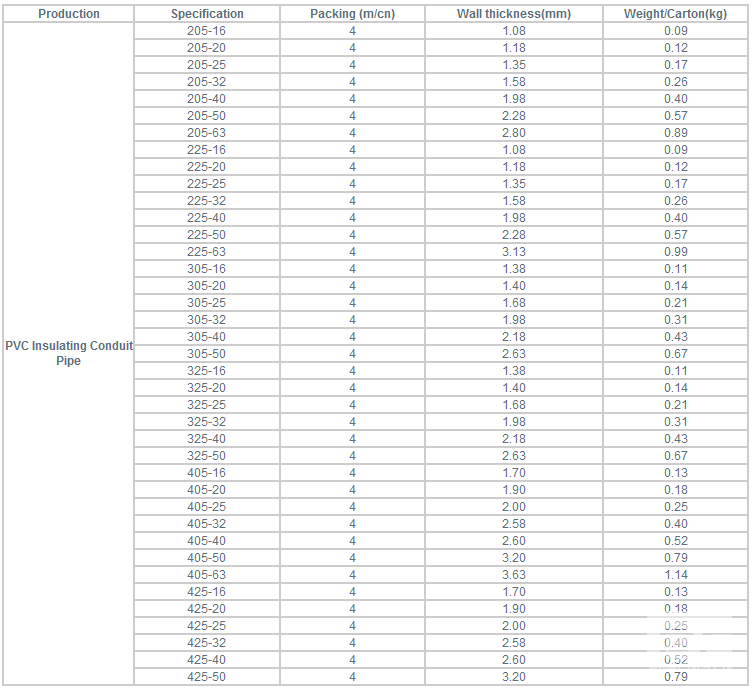

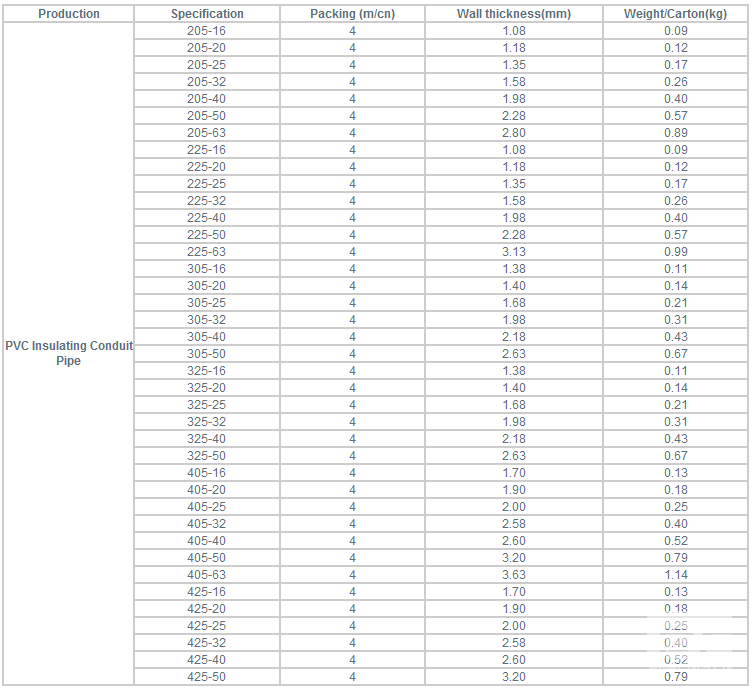

UPVC Insulating Conduit Pipe

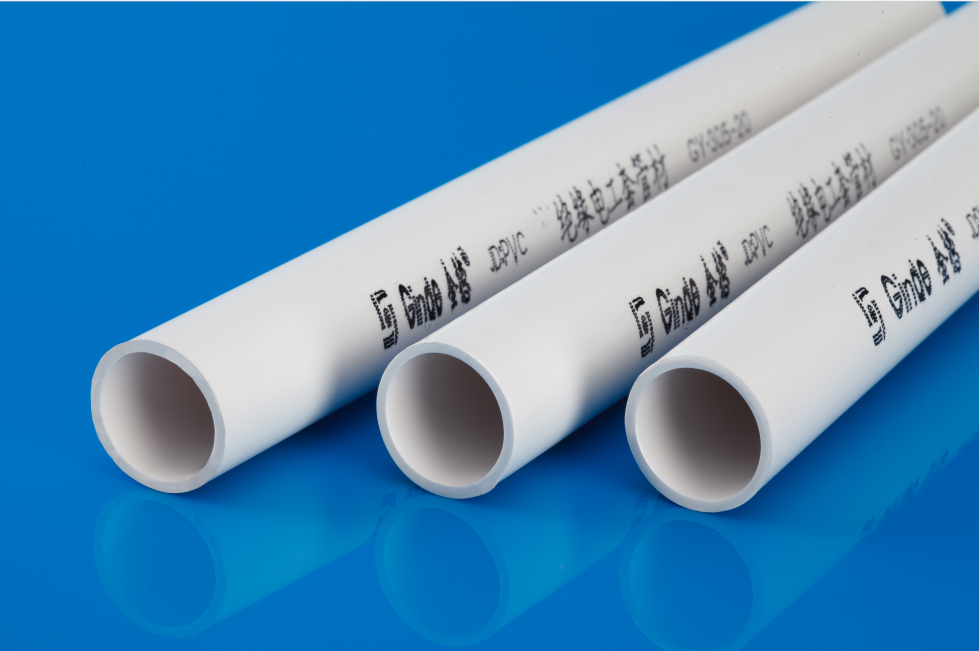

Ginde PVC insulation electrical conduit

Top-ranking equipment, advanced techniques, superior raw materials, scientific management and strict quality control have given the birth to top-ranking products. Ginde introduces advanced technologies and equipment from KRAUSSMAFFEI and Reimelt Company in Germany; use high quality polyvinyl chloride and imported auxiliary materials plus nano materials as raw material produces high quality of non-flammable PVC electrical cable with scientific formulas. Except lightweight, low cost, decent color and other advantages, Ginde PVC insulation electrical conduit also has following features:

1.Smooth surface of pipes and fittings and small friction coefficient reduces resistance to the electrical wires and cables in the pipeline

2.High resistance to pressure. Ginde conduit of mid size can stand above 750N pressure and can be externally installed or buried in concrete avoiding any damage caused by pressure.

3.Super resistance to impact and heat. In the processing of pouring concrete, Ginde conduit will not break under normal tamping bang and not melted by coagulation heat in construction process.

4.PVC conduit is moisture proof and has excellent resistance to acid, alkali and rust-eaten.

5.According to specification, each joint could be cemented with PVC adhesive to avoid water seepage and get better moisture resistant result. So it is suitable to be used in corrosive environment.

6.Flame retardant: Ginde PVC insulating electric engineering casing can be self extinguished when kept away from fire (it can be self-extinguished after leaving off flame for 30s), so fire can't be spreaded along the pipe.

7.It is insulated. In soaking condition, Ginde PVC conduit will not be broken down by the electricity of AC2000V, 50Hz. In aspect of avoiding electric shock, international tendency is that insulation is preferred to earth connection. Ginde PVC insulation electrical conduit meets this requirement.

8.Because PVC conduit has special additive, it will not emit smell attracting insects and mice biting it.

9.Easy installation. The conduit less than de32mm can be easily cut off by pipe cutter. Inserting relevant special spring into conduit, it can be bent into needed angle under normal temperature. Pipeline meeting the construction shape will be formed to connect conduits with PVC adhesive.

Technical requirements

Insulation electrical conduit is checked according to JG 3050-1998 standard. Following is the contents:

Appearance: Smooth surface, uniform thickness, diameter gauge with the smallest diameter, inside diameter using a minimum amount of regulation qualified surveyors gaugeBending test: at room temperature and low temperature (-150C), and bending machine into 1800C, no injury, no visible cracks

Compression test: loaded up to the specified value within 30 seconds, keeping the load for one minute, the deformation <25%; after unloaded for one minute, the deformation < 10%, the smallest inner diameter of pipe metering the free falling body has passed the test.

Impact test: pretreated with oven under 600C+20C for 240h; put the impact meter and the treared test piece into low-temperature cabinet for 2h; make it impacted by heavy hammer from the corresponding height for 12 times, at least 10 times without broken or visible crackings.

Heat-resistance test: under 600C, use steel ball with the diameter of 5mm to apply 20N force on the pipe wall and keeping for 1h, the diameter of the indentation 2mm.

Flame retardant test: use blowtorch to burn it continuously three times (each time for 25s and the time interval of 5s), it will be self-extinguished after leaving off fire for 30s.

Dielectric strength: place the sample in 230C+50Cwater; after 24h, apply 50Hz, 2000V voltage on it for 15m, the sample can't be broken through.

Insulation resistance: 100M(with DC500V voltage)

Flattening Strength: bend the pipe to 900, fix it on the steel bracket and place it to 600C?0Coven to be pretreated for 24h, the gauge can slipe from the casing in freely falling body.

Drop strength: after connected with fittings, it is placed in -200Clow temperature cabinet for 2h; it drop 1500mm high without being broken or crackings.

Production facility

Ginde Plastic Pipe Industry Group introduces complete set of production lines from Germany KRAUSS, which are the most advanced in current world. The most advanced design and fabrication technology are used for these production lines. They have following advanced performance: high-speed extrusion and molding, automatic Cut-to-Length, microcomputer software controls the whole production procedure. Microcomputer software system that is used for controlling production procedure can be inputted and set in advance according to production process specification, starting time, temperature-sensing standard and so on.

It will monitor, record and store automatically kinematic velocity of equipment electric motor and screw bolt, pressure of fused mass, extrusion output, torsion load, and modification of order data. It also can alarm danger, automatically stop and show modification proposal or note of correction on screen (there are three languages available). This can ensure good condition of equipments and normal production at all. Advanced design of mechanical structure adopts planoconic twin screw with 36D slenderness ratio and scientific unique compression ratio which combine perfectly with mechanical structure. It has following good performance: secondary air discharge, repeating compression, moderate fusing, and high-speed extrusion. It is also equipped with imported large-scale blend equipment which is provided with self-measuring delivery, sealing and dust-free, well-proportioned admixture and dispersion to ensure the continuous process of automatic production

Production technology of conduit

The company introduced injection mould machines from Hong Kong Zhenxiong Company to produce various fittings for PVC electrical conduits. Pipes and fittings are all designed reasonably by the specialist in company. They are pleasing in appearance, with a proper configuration, safe and convenient application. Rigorous testing and the use in large-scale projects have proven that the products fully comply the set of requirements.

Features of the product

1.Cold bending

When bending the insulation electrical sleeve of which diameter equal to or less than 25mm, insert the pipe with special spring, bending it according to needed length and angle. For bending and spring, pay attention to the following points:

A. Spring should not be distorted terribly, and no deformation. Unqualified spring will distort and damage pipe and be blocked inside pipe. Outer diameter of spring should be less than inner diameter 0.7~1mm. When bending longer pipe, one end of spring should be tied with rope in order to pull it out. Bending not more than 90 degrees is preferable. Bending radius of pipe20, R>50mm, bending radius of pipe 25, R>62.5mm.

B. Because pipe has rebound, it should be curved slowly after spring is inserted into pipe. Bending angle should be less than angle needed. In cold weather, the section which will be curved should be warmed up properly by repeating friction with cloth before bending it. If bending too fast, it is easy to damage pipe and spring.

C. If surface installation is adopted, bended pipe should be fixed with pipe clip. Spring should be pulled out slowly while it is anticlockwise rotated to avoid damage or blocking of spring. If bending angle is not meeting the requirement, pipe should not be pulled for returning to original condition by force to avoid damage of spring and pipe.

2.Heating bending

The tube of which radius is larger than 25mm should be curved by spray with hot water or hot gas, but not heated with fire. Spring should not be pulled out before pipe cool down. After full cooling of pipe, anticlockwise rotate spring and slowly pull it out. Bending not more than 90 degrees is preferable. When heat and bend pipe, pay attention to prevent wrinkling pipe wall and cool pipe with wet cloth

3.Bending pipes with pipe bender

Insert pipes into the supporting pipe bender and bend it to the needed bending with hand.

Matters needing attention

1.Tube bending should be proceed slowly without excessive speed,otherwise pipe and spring within the pipe may be damaged.

2.Before removing spring for bending pipes, do not bend elbow back so hard to prevent damage of spring.

3.When spring for bending is not easily removed, pull the spring while anticlockwise rotate it, because of shrinkage of spring diameter, and it will be removed.

4.If a longer tube, a piece of rope may be tied at the two ends of spring and spring can be dragged out by the rope after bending pipes.

5.If constructing in cold weather, the section which will be curved should be warmed up properly by repeating friction with cloth before bending it.

6.After the tube assembly, washing down, damage or injury should be prevented.