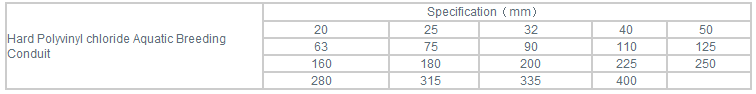

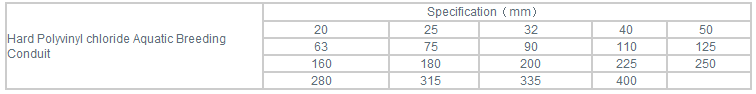

Hard Polyvinyl chloride Aquatic Breeding Conduit

Use

The new generation of environmental and health PVC-U breeding conduit is developed and produced in line with the green and health tenet. It is a new generation of cultivation piping system. It has many merits. For example, it is healthy and non-toxic; the operational performance is safe and reliable, and so on. It can be applied to the water transportation, oxygen transportation, waste water discharges and so on in the cultivation industry such as the sea water cultivation, the fresh water cultivation, and the animal husbandry cultivation. The suitable cultivation object should possibly be the shrimp, the crab, the abalone, the domestic animal, the domesticated fowl and so on.

Performance of raw material

Polyvinyl chloride resin is used as the carrier. Weakens the gravitation between the molecule chains in the resin, it has the excellent characteristics of accurate temperature, fixed time fuses, and rapid absorption of effective chemicalt. In the same time, by using the world superior name brand compound stabilizer "the bear" brand from Germany, we can catch, control, absorb and counteract the hydrogen chloride emerged when the resin fuses after high temperature. Duplet bond addition reaction can be carried on between this brand compound stabilizer and the alkene structure, and then the lively and unstable chlorine atom is permuted from the molecule. Thus the catalyzed degeneration and the oxygenolysis in the resin under the fuses condition are controlled effectively and scientifically.

Producing equipment

Our company imports the plastic extruder (extruded stubbing) from Germany Krauss Maffei Company that adopts the most advantage technology for design and production. The advanced performances are fast extruding molding; automatically cut with fixed size, hot-melt expansion on line and microcomputer software controlling all producing process.

ln the microcomputer (C4) controlling the production process, the starting time, temperature controlling standard can be preliminarily input and set according to the process specifications of the produce working. At the same time, the modification of the running speed, melt pressure, extruding outcome, twisting force load and regulations data and so on will automatically be monitored and recorded, storage for reading, dangerous condition warning, automatically closing down and display the modification advice or correcting description. (Can be read for three languages), so it can guarantee the no damage of the equipment and the normal running of the production process at all.

In the advanced mechanical structure design, the rate between length and diameter is 36D. The flat cone-shape double screw rod is adopted, as well as the science unique compression ratio technological design, which forms the unification perfect union with the mechanism configuration. Such kind of structure design has superior performances of secondary air outlet, repeating compression, melting moderation and fast extruding process. At the same time, the large scaled import mixing equipments from Lai Mater in Germany of automatically computation transportation, closed with no dust, mixing dispersed equably, which can guarantee the continuous process of production processing automation.